friction stir spot welded aluminum alloy 2024 – The most common aluminum alloys (read more) Browse Stainless Steel Alloys Datasheets for Eagle Stainless Tube & Fabrication, Inc. 2011) Effect of welding parameters on microstructure and mechanical . Friction welding (also known as stir welding), is the process of taking two pieces of material (typically metal, or plastic), and vibrating one of them super fast while pushing against a .

friction stir spot welded aluminum alloy 2024

Source : www.sciencedirect.com

Tool torque and pin temperature output during friction stir spot

Source : www.researchgate.net

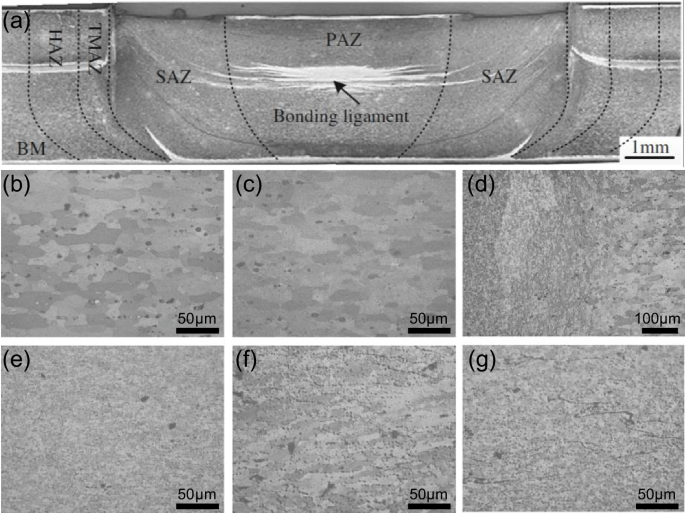

Dissimilar friction stir spot welding of AA2024 T3/AA7075 T6

Source : www.sciencedirect.com

XRD Pattern for the base metal and friction stir spot welds at 15

Source : www.researchgate.net

PDF] Effect of Tool Pin Geometry on Microstructure and Temperature

Source : www.semanticscholar.org

a) Schematic of friction stir spot welding driven diffusion bond

Source : www.researchgate.net

Refill friction stir spot welding of aluminum alloys: State of the

Source : link.springer.com

TEM micrograph showing voids. In stir zone of an Al 2024 spot weld

Source : www.researchgate.net

Friction stir spot welding of aluminum and carbon fiber reinforced

Source : www.sciencedirect.com

Schematic of the refill friction stir spot welding a) through d

Source : www.researchgate.net

friction stir spot welded aluminum alloy 2024 Dissimilar friction stir spot welding of AA2024 T3/AA7075 T6 : Researchers at the U.S. Army Aberdeen Proving Ground Research Laboratory were developing a high-strength aluminum alloy when they made a startling discovery. During routine testing of the alloy . Images of aluminum alloy 7075 taken with a scanning electron microscope before (A), during (B), and after (C) going through the ShAPE machine show how the microstructure of the alloy changes .